The next stage was to remove more of the loom tape, so I could see what was going on!

Above you can see all the cables heading to and from the ECU connector.

Interestingly, a number of wires head towards the body loom connectors (the majority go to the blue C120 connector) - and these are the wires that the C0159 MEMS3 body loom connector splice into. Here I've started to snip away at these, but you can see how the wires double back from the MEMS plug to the body plug connector loom:

After a while of matching wires, I ended up with this:

I've grouped wires temporarily together with masking tape - it will get proper loom tape later.

At around this point I discovered I had a problem. I don't know the provenance of the connector, but wasn't wired in the way I was expecting from the research I'd done (as shown above in this thread). Nothing too dramatic - no engine bay fan cable and no sensor earth connector - in other words, nothing that would necessarily stop the engine from working. Annoyingly, a number of the wire colours on my connector did not match the MGF engine loom - so presumably it wasn't originally from a MGF or TF. Still, knowing the pin locations meant that I could work out what should connect to what. But if you are planning this conversion, it is best to obtain everything you need from a single donor MGF or TF.

There were also a couple of wires left over on the MEMS1.9 loom too: MEMS3 doesn't have a lambda sensor relay, so this is now redundant in the MRU. There is also an engine bay sensor, which later versions of MEMS3 do not use. Earlier versions do, and I may need to work out what pin that should go to as the MEMS3 ECU I plan to use, I think, comes from an earlier 120PS 1.8K.

So at this point I was faced with some bad news: a C0159 plug which was short of a couple of cables, and had a bunch of others that I didn't need (mostly related to automatic gearbox function I think)

One of the C0159 connectors that Tony gave me was actually broken, so I thought I would have a look at this to see how these go together, as the on-line PDFs of this connector weren't particularly illuminating! Sorry, I haven't got any pictures of this part of the process - a process that unfortunately it lead to a more broken connector than it was before! But it yielded valuable information, plus a few spare cables and water-proof bungs

The upper casing can be removed. Don't be tempted to pry the outer tags out: these are made of brittle, hard plastic, and they will snap. Guess how I found that out

The upper casing can be pushed in, and the barbs pried out to reveal the wire insertion into the plug.

- The upper cover of the C0159 plug can be pressed in, so barbs clear main plug body

Each of the connectors has a barb - so they don't just pull out. But luckily, there is a locking mechanism that can be unlocked from the plug-side of the connector: put it to the opposite side, and the wire and the female connector pins can be pulled out. This won't make any sense - so I shall try to remember to take some pictures of the dissected C0159 connector - it may prove of use to others!

Edit - pictures added below:

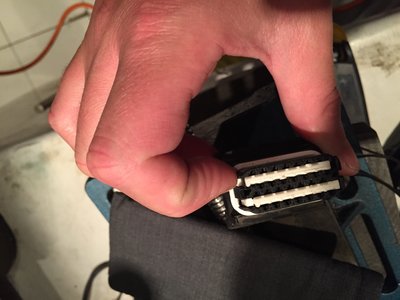

- Underside of the C0159 plug. Note two white coloured inserts - this is the secondary locking mechanisms that prevent the female connector pins from falling out.

- To lock or unlock, push the white locking mechanism from side to side.

- Here I have removed the locking mechanism - see how little "L"-shaped bays are molded in? Pushing it to one side locks the connector barb in position, but to the other opens a channel where the pin can be withdrawn.

Having mastered the technique on the now completely destroyed connector, I could safely re-wire the C0159 to suit my application

Just want to show another picture now - the now redundant MEMS1.9 connector with the cables cut to splice in the MEMS3 C0157 connector

I've got just a couple more wires to solder (the three earth cables, and work out which wire to pick up the switched live power), and it is nearly job done before moving onto grafting these MEMS1.9 plugs to the MEMS3 engine loom